Visual Fault Locators: Fast Troubleshooting for Fiber Breaks

Fiber optic networks form the backbone of modern communications, enabling high-speed internet, enterprise connectivity, and mission-critical systems in industries from telecom to aerospace. But even the most carefully installed fiber can develop issues—breaks, bends, or connector damage that lead to signal loss and costly downtime. For technicians, speed matters: the faster a fault is found, the sooner service is restored.

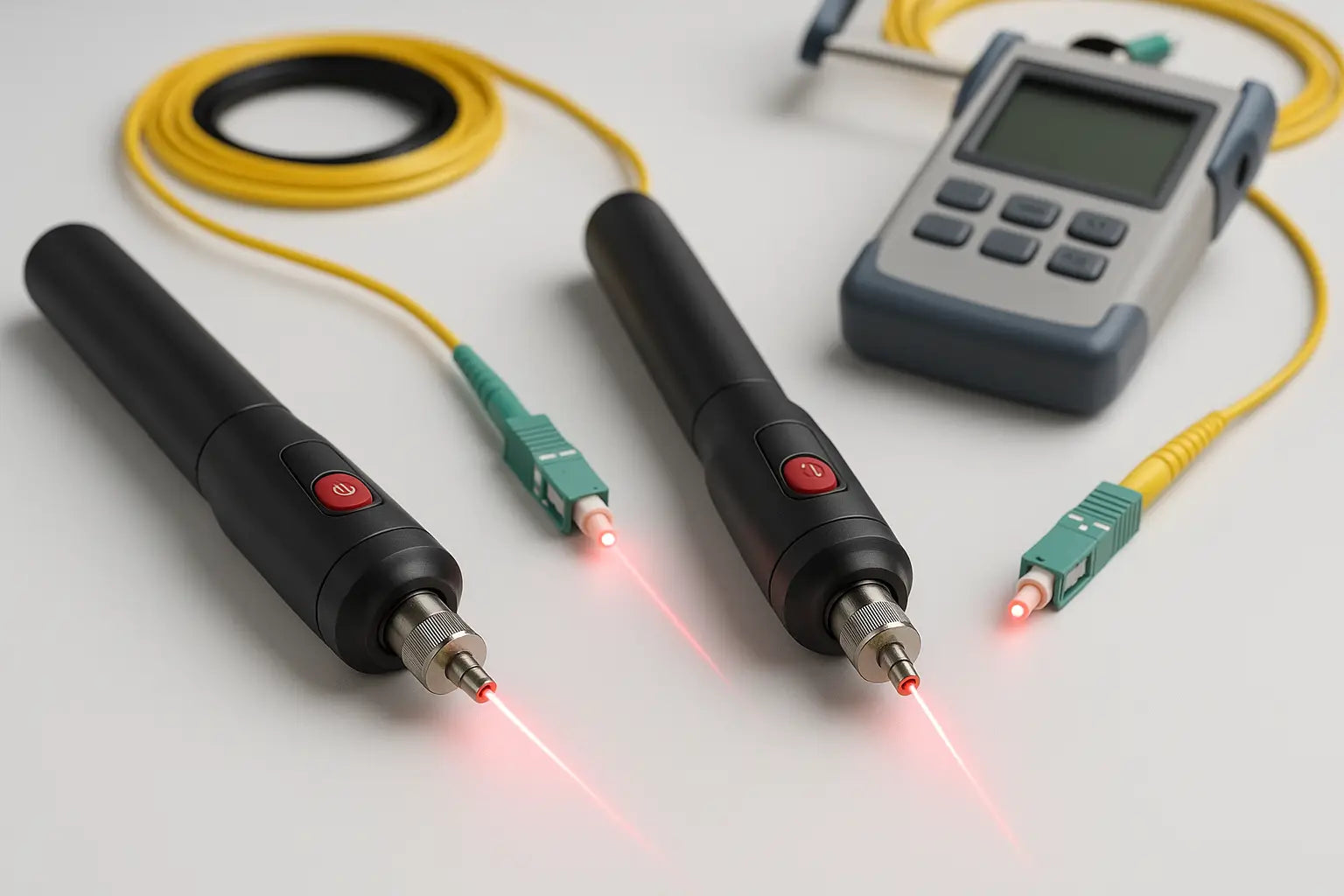

That’s where Visual Fault Locators (VFLs) come in. Simple, affordable, and highly effective, VFLs are one of the most indispensable tools in a fiber technician’s kit.

What Is a Visual Fault Locator and How Does It Work?

A VFL is a handheld device that injects a visible red laser (typically 650–670 nm) into a fiber cable. When the light encounters a break, a bad splice, or a sharp bend, it leaks through the cladding and becomes visible to the naked eye. This makes it easy to spot exactly where the problem lies.

Key points about VFL operation:

-

Works with single-mode and multimode fibers.

-

Supports various connectors via universal adapters or patch cords.

-

Operates over short-to-moderate distances—ideal for patch panels, jumpers, or in-building runs.

Advantages of Using Visual Fault Locators

-

Immediate Visual Feedback – Instantly confirms continuity or identifies a break.

-

Low Cost, High Value – Far cheaper than advanced optical testing gear but still extremely effective.

-

Portable and Rugged – Fits easily in a pocket or toolkit for field or lab use.

-

Great for Training – A perfect educational tool to show technicians what fiber failures look like.

Limitations and When to Use Other Tools

VFLs are best for locating visible, physical faults. They don’t measure optical power loss or reflectance and aren’t suitable for long-distance links. For full diagnostics or certification testing, pair a VFL with tools like:

-

Loss Testers – Measure insertion loss to verify network performance.

-

Optical Time-Domain Reflectometers (OTDRs) – Pinpoint events along long-haul fiber runs.

-

Fiber Inspection Scopes – Check connectors for dirt or scratches that can mimic faults.

Using VFLs alongside these tools ensures you’re not just locating problems but also validating network quality.

Practical Scenarios for Visual Fault Locators

-

Field Installations – Verify splices, patch cords, and connectors as you go, preventing expensive rework.

-

Routine Maintenance – Quickly check suspect fibers during scheduled inspections.

-

Emergency Repairs – Reduce network downtime by immediately locating damage after construction accidents or equipment movement.

-

Training Programs – Show technicians how light behaves in damaged fibers, reinforcing theory with a hands-on demonstration.

-

Patch Panel Management – Use a VFL to trace fibers through complex panels and ensure proper routing.

Best Practices for VFL Use

-

Use a Launch Cable or Adapter: Prevents wear on primary connectors.

-

Inspect First: Use a Fiber Inspection Scope to clean connectors—dirt can cause false indications.

-

Mind Eye Safety: Never look directly into the laser or into a fiber connected to an active system.

-

Verify with Loss Testers: Always confirm network performance after repairs to ensure compliance.

Complementing VFLs with Loss Testers

While a VFL can show you where light is leaking, Loss Testers provide a quantitative measurement of signal loss across the link. This is essential for certifying new installations or troubleshooting subtle performance issues that may not be visible with a VFL alone. TT Instruments offers a range of Loss Testers that integrate seamlessly into fiber workflows.

Why Shop TT Instruments for Fiber Testing Tools

TT Instruments carries a complete range of professional Visual Fault Locators and Loss Testers trusted by technicians, contractors, and network engineers. Every tool is tested for performance and durability, ensuring accurate results in demanding environments. Whether you’re performing routine inspections, handling emergency repairs, or certifying a new network build, our equipment helps you troubleshoot quickly and confidently.

FAQs

1. What does a Visual Fault Locator do?

It injects a visible red laser into a fiber, making breaks, bends, or bad splices glow for easy identification.

2. How far can a VFL trace a fiber?

Most VFLs are effective for distances up to 5–10 km, depending on the fiber type and conditions.

3. Can I use a VFL on live fiber links?

No. VFLs should only be used on non-active fibers to avoid damage or inaccurate readings.

4. Why pair a VFL with a Loss Tester?

A VFL identifies visible faults, while a Loss Tester quantifies signal loss—together they ensure network performance.

5. Are VFLs compatible with all fiber types?

Yes, they work with both single-mode and multimode fibers using standard connectors or adapters.