Fusion Splicers vs. Mechanical Splices: What’s Best for Your Project?

When building or repairing fiber optic networks, joining fibers is unavoidable. Two primary methods—fusion splicing and mechanical splicing—offer different advantages depending on your project’s needs. Understanding their differences can save time, money, and ensure long-term reliability.

Fusion Splicing: Precision and Durability

Fusion splicing uses an electric arc to permanently join two fibers. Fusion Splicers align the fiber cores with extreme accuracy, then fuse them together for a nearly seamless connection. This method offers:

-

Low insertion loss and reflectance – essential for high-performance networks.

-

Permanent, durable joints – ideal for long-term installations.

-

Better reliability in harsh environments – especially important in telecom, industrial, or outdoor applications.

While fusion splicing offers superior performance, it requires specialized equipment and a skilled operator. TT Instruments offers a range of Fusion Splicers to meet professional needs.

Mechanical Splicing: Fast and Cost-Effective

Mechanical splicing aligns fibers inside a pre-made sleeve or holder, secured with index-matching gel. It doesn’t require electricity or expensive tools, making it appealing for:

-

Quick repairs or temporary fixes – when uptime is critical.

-

Lower initial investment – ideal for small-scale projects or budget-conscious teams.

-

Situations where portability matters – useful for field technicians without access to full splicing gear.

However, mechanical splices generally have higher loss and may not last as long as fusion splices.

Choosing the Right Approach

Your choice depends on factors such as budget, required performance, and project scale. Large networks or long-term installations usually benefit from fusion splicing, while small repairs or temporary connections may be more practical with mechanical splices.

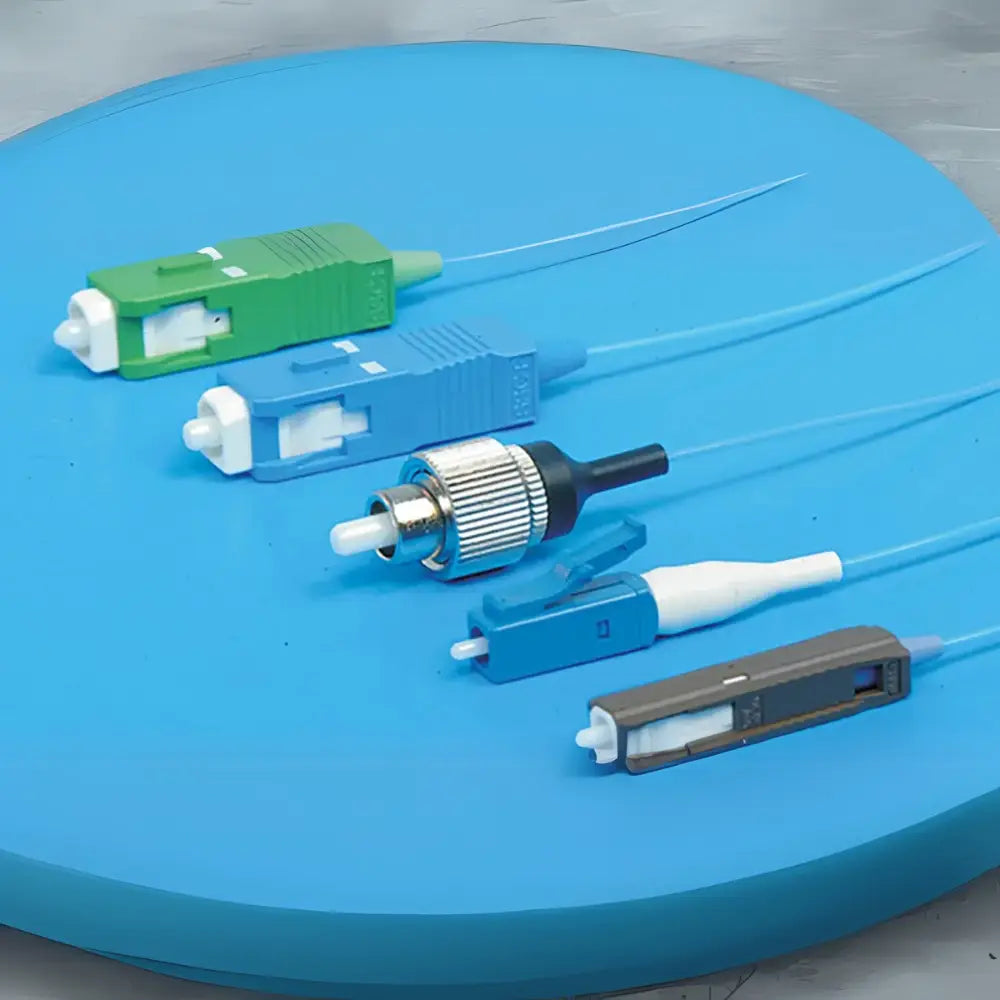

To complete your fiber build or repair, don’t forget Passive Components such as connectors, adapters, and attenuators—they’re essential for maintaining signal integrity after splicing.

Why Shop at TT Instruments

TT Instruments provides a wide selection of Fusion Splicers and Passive Components, ensuring you have the right tools and accessories for your project. Whether you’re upgrading a network or fixing a critical connection, our equipment is tested and trusted by professionals.

FAQs

1. What is the main difference between fusion splicing and mechanical splicing?

Fusion splicing permanently melts fibers together for minimal signal loss, while mechanical splicing uses alignment sleeves and gel for a quick but less durable join.

2. When should I use a mechanical splice instead of a fusion splice?

Mechanical splices are great for temporary fixes, small repairs, or when budget or portability is a concern.

3. Why are fusion splicers preferred for high-performance networks?

Fusion splicers create strong, low-loss connections that ensure long-term reliability—critical for telecom, enterprise, and industrial networks.

4. What passive components are needed after splicing?

Connectors, adapters, and attenuators are common passive components that help maintain signal quality after splicing.

5. Does TT Instruments provide both splicing tools and accessories?

Yes, we offer high-quality fusion splicers and passive components to support every stage of your fiber optic project.