Visual Fault Locators: Fast Troubleshooting for Fiber Breaks

Fiber optic networks are critical to modern communication, data, and industrial systems. Their reliability depends heavily on the integrity of the optical fibers that carry light signals. When those fibers develop breaks, bends, or poor splices, performance can degrade rapidly—leading to costly downtime or weak connections.

For field technicians and installers, speed and accuracy are everything. You need to identify faults quickly, confirm repairs, and move on. That’s where Visual Fault Locators (VFLs) come in—compact, affordable, and indispensable tools that help locate fiber problems instantly.

What Is a Visual Fault Locator and How Does It Work?

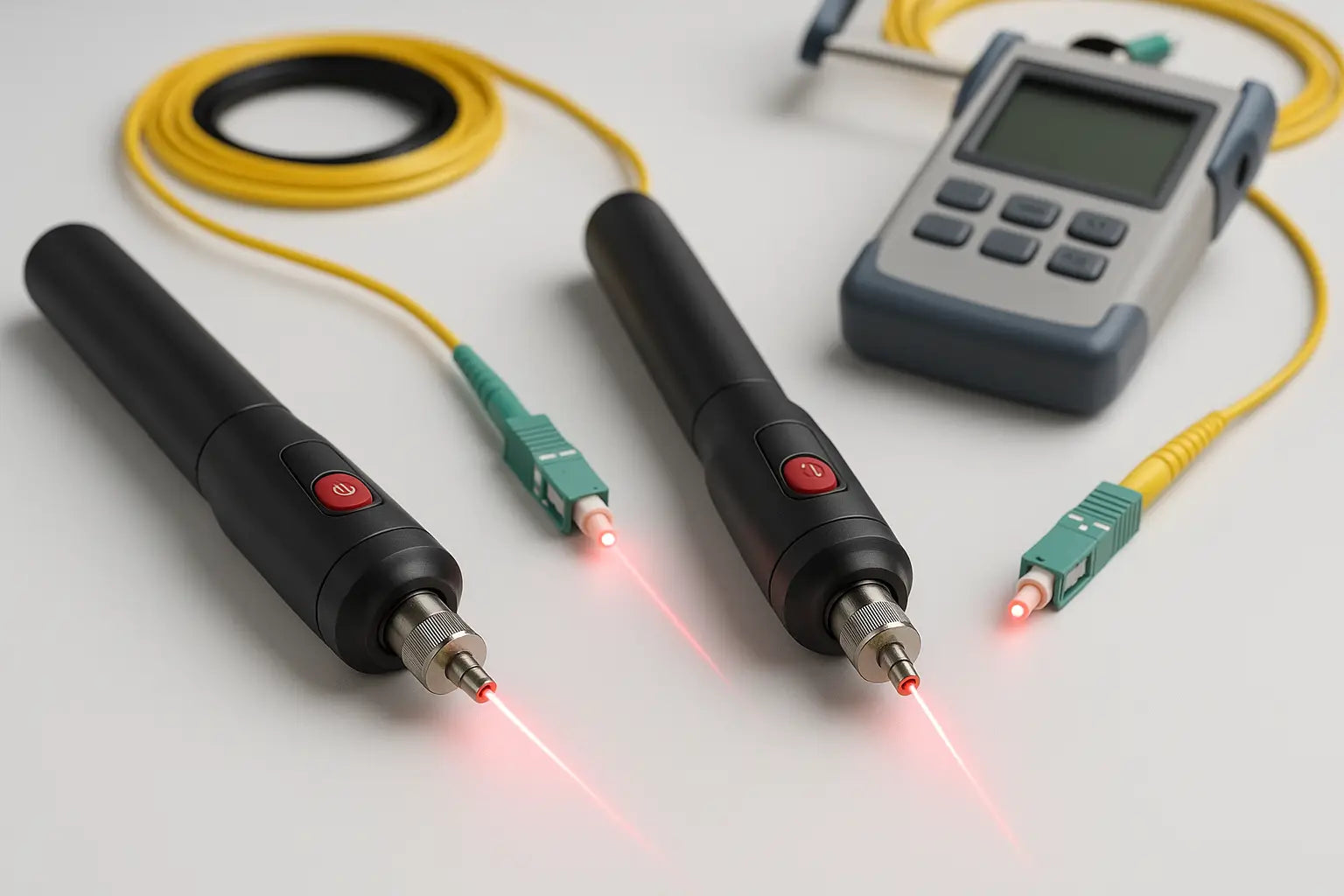

A Visual Fault Locator is a simple yet powerful diagnostic tool that injects a bright visible red laser (typically 650–670 nm) into a fiber. When the light encounters a fault—such as a break, bad splice, or sharp bend—it leaks through the fiber cladding, making the issue visible to the naked eye.

Because they’re lightweight and battery-powered, VFLs are ideal for field use and can work with both single-mode and multimode fibers. Many models include universal connectors, allowing them to connect easily to patch cords or test leads.

Common Fiber Issues a VFL Can Detect

-

Fiber Breaks: The most obvious fault—visible light leakage shows the exact break point.

-

Bends or Pinches: If the fiber is bent beyond its minimum radius, the light will escape at that spot.

-

Connector Problems: Poor terminations or dirty connectors show red glow at the joints.

-

Splice Errors: Misaligned or damaged splices become visible, helping technicians fix them immediately.

VFLs are especially useful during installation, quick maintenance checks, or after handling fiber cables in tight spaces.

Advantages of Using a Visual Fault Locator

-

Immediate Feedback – No waiting for test results or advanced analysis—just plug in and see where the issue is.

-

Portable and Cost-Effective – Small enough to fit in a pocket, yet capable of preventing major network issues.

-

Easy to Use – Requires minimal training and setup.

-

Versatile Applications – Works across various fiber types and environments, from telecom sites to industrial plants.

The Limitations—and the Role of Loss Testers

A VFL is excellent for quick visual troubleshooting, but it’s not designed for full network certification or performance validation. It can show where light is escaping, but not how much signal is lost over a link.

That’s where Loss Testers come in. A Loss Tester measures insertion loss—the total amount of optical power lost between two endpoints. Using both tools together provides a complete diagnostic picture:

-

The VFL finds the physical fault location.

-

The Loss Tester quantifies the optical performance of the fiber.

Technicians often use both tools during installation, maintenance, and final certification stages.

Practical Scenarios for VFL Use

-

Field Installations: Verify splices and connectors on the spot before closing joints or cabinets.

-

Maintenance Checks: Test cables after movement or environmental stress to confirm integrity.

-

Training Labs: Demonstrate how fiber light travels and where it fails—ideal for technician education.

-

Emergency Repairs: Quickly locate and fix damaged fibers after construction or accidental pulls.

-

Patch Panel Identification: Use a VFL to trace fibers in large distribution panels easily.

Best Practices for Using a Visual Fault Locator

-

Always clean connectors before testing to prevent dirt from blocking light output.

-

Use launch cables to protect main connectors from wear.

-

Never look directly into the fiber end when using a VFL—use proper eye safety precautions.

-

For long-haul testing, pair your VFL with an Optical Time Domain Reflectometer (OTDR) for detailed event mapping.

Shop Visual Fault Locators and Loss Testers at TT Instruments

At TT Instruments, we offer a professional range of Visual Fault Locators and Loss Testers designed for technicians, engineers, and installers. All instruments are tested and calibrated to ensure consistent, reliable results—whether you’re troubleshooting, certifying, or maintaining fiber optic networks.

Our catalog includes:

-

Visual Fault Locators for fast visual inspections

-

Loss Testers and Optical Power Meters for performance measurement

-

OTDRs and Inspection Scopes for advanced diagnostics

Explore our Fiber Optics category for the right tools to keep your network performing at its best.

Precision in Every Connection

Troubleshooting fiber doesn’t need to be complex or time-consuming. With a Visual Fault Locator in your toolkit—and complementary tools like Loss Testers—you can identify and fix problems in minutes, not hours. Reliable fiber networks start with accurate testing, and the right tools make all the difference.