Field Testing Fiber Optic Networks: Tools and Techniques

Fiber optic networks are the backbone of modern high-speed communication, and ensuring their integrity requires more than just quality installation—it requires precise, reliable field testing. Whether you’re a seasoned fiber technician or building your toolkit, understanding the essential tools and testing techniques will help ensure performance, minimize downtime, and meet certification standards.

Core Testing Tools for Fiber Optic Field Work

A streamlined fiber optic test workflow typically involves a combination of equipment, each playing a distinct role. Here are the key tools used by field professionals:

OTDR (Optical Time Domain Reflectometer)

The OTDR is a primary diagnostic tool in any fiber installer's kit. It sends pulses of light into the fiber and measures reflections caused by splices, breaks, or other issues.

Use cases:

-

Measuring fiber length and splice loss

-

Locating faults or breaks

-

Creating fiber link certification reports

Check out our range of OTDRs at TT Instruments for field-ready models with trace analysis and handheld form factors.

Loss Testers & Fault Locators

These testers measure insertion loss across the fiber to ensure minimal signal attenuation. They’re used in tandem with light sources and power meters to confirm link quality.

Loss testers are especially useful during:

-

Link certification after installation

-

Troubleshooting connectivity or signal degradation issues

Explore our Loss Testers & Fault Locators category for reliable options tailored to single-mode and multi-mode fiber.

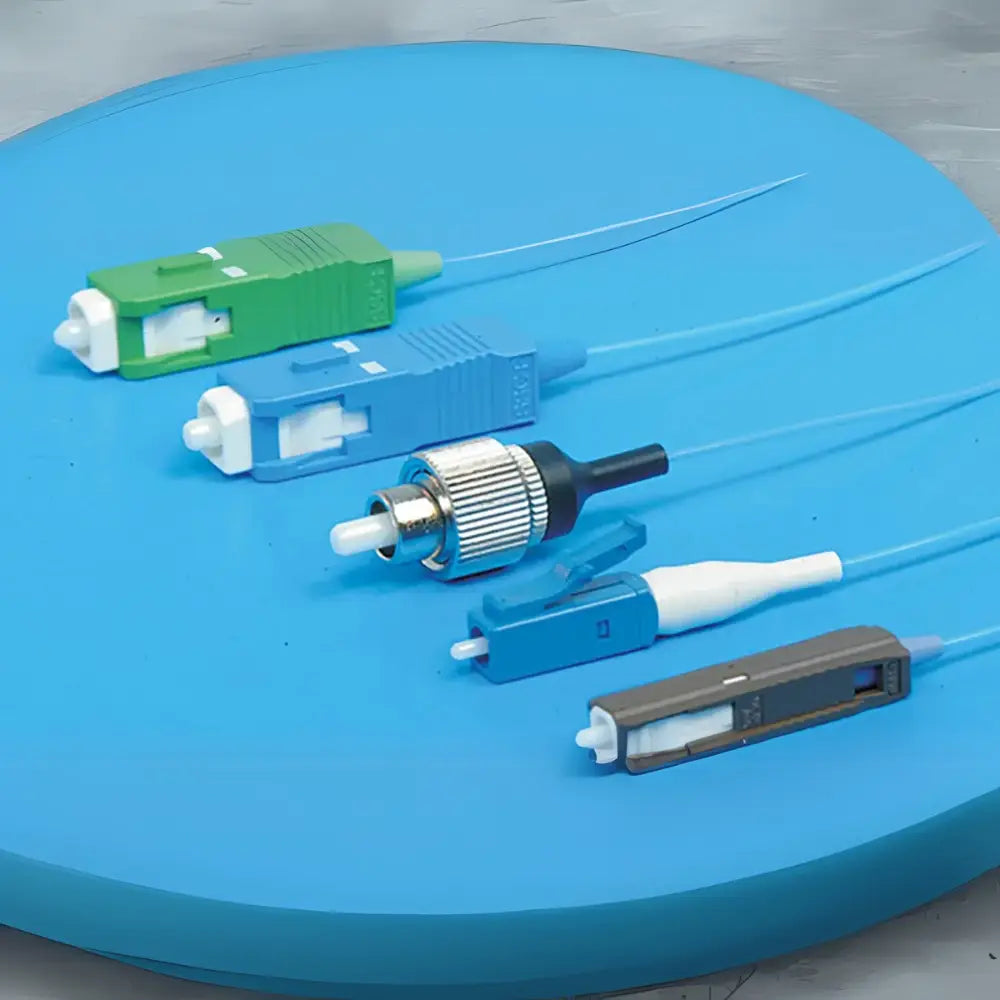

Fiber Inspection Scopes

Before testing or connecting, it's crucial to inspect the connector endfaces for dust, dirt, or scratches. Contamination is the number one cause of signal loss in fiber optics.

A good Fiber Inspection Scope:

-

Magnifies the connector endface to spot defects

-

Supports automatic pass/fail analysis

We offer scopes for both field and lab use in our Fiber Inspection Scopes section.

Other Essential Tools in the Fiber Toolkit

Fusion Splicers

Fusion splicers weld two fibers together with minimal loss. Proper splicing technique ensures signal continuity and durability in the field.

Explore options in our Fusion Splicers category, ideal for high-precision and fast deployment scenarios.

Fiber Cable Certifiers

Certifiers validate a fiber link's compliance with industry standards. They combine several functions, including power measurement, loss testing, and certification report generation.

Browse Fiber Cable Certifiers for all-in-one tools suited for installers, auditors, and network technicians.

Modular Testing Platforms

Modular systems let technicians add or remove modules for OTDR, inspection, or certification, offering versatility without carrying multiple standalone devices.

Our Modular Testing Platforms are designed for scalability and customization on-site.

Optical Attenuators & Passive Components

These components let you simulate real-world signal degradation or isolate parts of the network for testing without disconnecting the main link.

Check out our Optical Attenuators and Passive Components for controlled, repeatable testing scenarios.

Common Errors and How to Avoid Them

-

Skipping Endface Inspection

Dirty or damaged connectors are a leading cause of test failure. Always inspect before connecting. -

Misinterpreting OTDR Traces

Reflections at connectors or splices can resemble faults. Familiarize yourself with the signature patterns of normal vs. abnormal readings. -

Not Accounting for Test Lead Length

OTDRs require launch cables to provide a baseline reading. Ensure the lead fiber is long enough to accurately detect the first event. -

Ignoring Wavelength Mismatch

Always test using the correct wavelengths (typically 1310nm and 1550nm) as losses vary by wavelength.

Safety and Handling Tips

-

Always use protective caps on connectors when not in use.

-

Never look into a live fiber—infrared laser light is invisible and can damage your eyes.

-

Store fiber tools in dust-free, padded cases to maintain calibration and optical alignment.

Outfitting Your Fiber Field Kit with TT Instruments

Whether you're building your kit from scratch or upgrading to new capabilities, TT Instruments offers a wide selection of fiber optic test equipment, including new and certified used gear. With categories ranging from OTDRs to Fusion Splicers and Inspection Scopes, we support your work with tools that combine precision, durability, and field-friendly features.

Want help choosing the right tool? Our team can assist with application-based recommendations.

FAQs

1. What is an OTDR and why is it used?

An OTDR (Optical Time Domain Reflectometer) is used to locate faults, measure fiber length, and assess splice loss by analyzing light reflections in the fiber.

2. Do I need both a loss tester and an OTDR?

Yes. An OTDR is excellent for pinpointing issues and documenting the fiber’s physical condition, while a loss tester measures signal attenuation between endpoints.

3. How often should I inspect fiber connectors?

Every time before connecting or testing. Dirty or damaged connectors can drastically affect performance and test accuracy.

4. Are modular platforms better than standalone tools?

Modular platforms offer flexibility by allowing different test modules to be swapped in, making them ideal for diverse testing needs or upgrading over time.

5. What’s the safest way to handle fiber optics during testing?

Always keep connectors clean and capped, use proper inspection tools, and never look directly into a fiber—IR light can be dangerous even if invisible.