From OTDRs to Inspection Scopes: Navigating Fiber Test Equipment

Understanding Fiber Optic Test Equipment

A Guide for Network Installers and Engineers

As global demand for high-speed data transmission continues to grow, fiber optic networks are becoming the backbone of modern communication systems. Whether it’s for enterprise infrastructure, telecommunications, or data centers, ensuring the integrity and performance of fiber optic cabling is critical.

For network installers and engineers, understanding how to properly test, certify, and troubleshoot fiber connections is just as important as the physical installation. This guide introduces the key types of fiber optic test equipment used in the field and the lab—and how each tool contributes to a reliable optical network.

OTDR: The Backbone of Fiber Characterization

An Optical Time Domain Reflectometer (OTDR) is one of the most powerful tools in a fiber installer’s toolkit. It sends pulses of light through the fiber and measures reflected signals to provide a visual representation of the fiber’s length, attenuation, and connection quality.

OTDRs help pinpoint issues like breaks, bends, and poor splices, even in long-distance links. They’re especially valuable for acceptance testing and documentation in both new installations and maintenance tasks.

Explore our range of OTDRs designed for accurate, field-ready testing.

Power Meters and Light Sources

For loss testing and verification of signal strength, installers use optical power meters and light sources. These tools are often used together to measure insertion loss and ensure proper signal delivery along a fiber link.

Advanced instruments combine these features in Loss Testers & Fault Locators, which simplify the workflow and quickly identify low-signal areas, breaks, or excessive attenuation.

Browse Loss Testers & Fault Locators for reliable signal assessment tools.

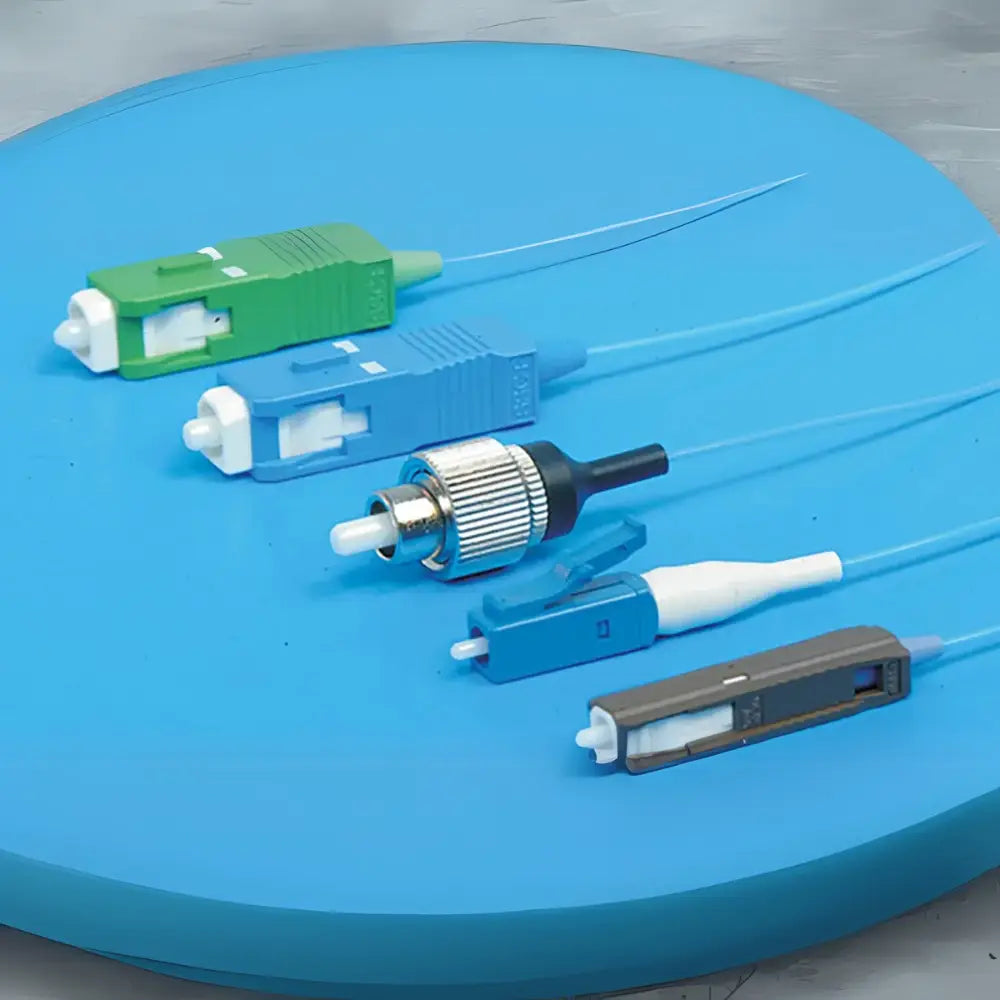

Fiber Inspection and Endface Quality

Clean fiber endfaces are essential for strong connections. Even microscopic debris can cause high loss or reflection. That’s where Fiber Inspection Scopes come in.

Inspection scopes allow technicians to visually check connectors and patch panel ports before mating, reducing the risk of contamination-related failures.

Check out our lineup of Fiber Inspection Scopes for handheld and bench-top inspection.

Certification and Compliance Testing

When working with enterprise networks or structured cabling, certification is often required. Fiber Cable Certifiers are designed to test multimode and single-mode fiber links against industry standards like TIA and ISO, producing detailed reports for handover and documentation.

These tools streamline compliance checks and are often used in data center and campus-wide installations.

Explore Fiber Cable Certifiers for professional-grade verification.

Advanced Signal Analysis

High-speed and long-haul optical networks demand deeper insight into signal integrity. Instruments like OSA/OCA/CD/PMD Analysers help analyze optical spectrum, chromatic dispersion, and polarization mode dispersion—critical parameters for high-performance DWDM and coherent systems.

These tools are mainly used by engineers involved in network design, R&D, and high-capacity transmission systems.

Discover our OSA/OCA/CD/PMD Analysers for advanced optical diagnostics.

Fiber Splicing and Passive Components

Creating permanent fiber links often involves fusion splicing. Fusion Splicers precisely align and join fiber ends, delivering low-loss, durable splices. They're widely used in fiber deployment projects, from FTTx to metro networks.

We also supply Passive Components such as couplers, attenuators, and splitters—essential building blocks in both active and passive optical networks.

Shop Fusion Splicers and Passive Components for your installation needs.

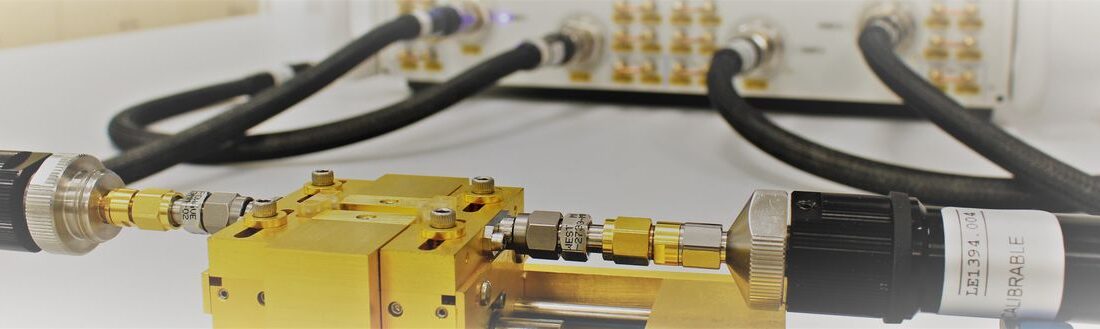

Modular and Scalable Solutions

For teams working across different network types or with changing test requirements, Modular Testing Platforms offer flexibility. These systems support interchangeable modules for OTDR, loss testing, inspection, and more—ideal for central offices, large-scale projects, or multi-technology environments.

Explore our Modular Testing Platforms for scalable fiber testing.

Final Thoughts

Fiber optic testing plays a critical role in ensuring reliable network performance. Whether you’re building a new link or troubleshooting an existing one, using the right combination of tools—from OTDRs and loss testers to inspection scopes and analyzers can save time, reduce errors, and improve long-term reliability.

At TT Instruments, we provide a wide range of fiber optic test equipment for installers, technicians, and engineers. Our inventory includes new and used tools from trusted manufacturers, backed by support and service that help you get the job done right.

Explore our Fiber Optics category to find the right solutions for your network projects.

Frequently Asked Questions: Fiber Optic Test Equipment

1. What is an OTDR and when should I use it?

An OTDR (Optical Time Domain Reflectometer) is used to analyze the integrity of fiber optic cables by detecting reflections and loss events along the fiber. It's best for locating breaks, splices, and connectors in long-distance or complex fiber runs.

2. What's the difference between a power meter and an OTDR?

A power meter measures the amount of light passing through a fiber, while an OTDR maps the entire fiber link, showing the location and severity of faults or losses. Power meters are ideal for simple signal checks; OTDRs are used for in-depth diagnostics.

3. Why is fiber inspection important before connecting cables?

Dirty or damaged connector endfaces can cause high insertion loss or reflectance. Fiber inspection scopes help detect contamination and defects before mating connectors, preventing signal issues and ensuring long-term reliability.

4. What do fiber certifiers test for?

Fiber cable certifiers check a fiber link against industry standards for length, loss, and polarity. They generate detailed reports for quality assurance, network documentation, and compliance with installation contracts.

5. Can I use the same equipment for both single-mode and multimode fiber?

Some test equipment supports both types, but it's essential to match the tool to the fiber type. For example, OTDRs, light sources, and power meters must operate at appropriate wavelengths (1310/1550 nm for single-mode; 850/1300 nm for multimode).

6. What is a modular testing platform and who should use it?

A modular testing platform allows technicians to swap test modules depending on the task—such as OTDR, loss testing, or inspection. It's ideal for service providers, large installations, or labs needing versatility in one device.

7. What are common causes of high loss in fiber optic links?

Common causes include dirty connectors, poor splicing, sharp bends, or fiber breaks. Proper inspection, cleaning, and testing during installation can significantly reduce these issues.